Depends if there are ticks on the back. If there is then definitely but if the book looks 9.8 I’m just solidifying it I just press it once.

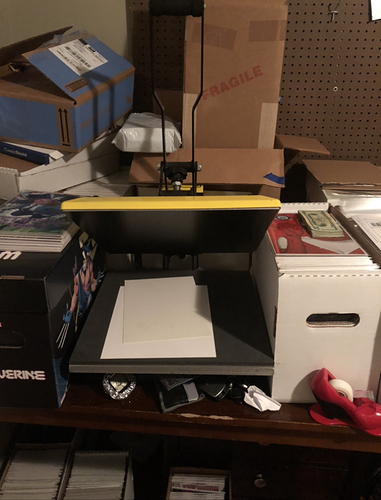

I use 2 magazine sized boards 1 silver age sized board(for the centerfold slipped in between the staple and cover) and a new sheet of parchment paper over the top of the book in between the cover and a magazine sized board. Stacking order from bottom up:

Magazine sized board

Comic with silver age board at the centerfold

Parchment paper (new sheet every time)

Magazine board

I used to use a silicon sheet but found that over time it attracts dust and hair and whatnot so for me it was best to use new parchment paper each time.

My press is in my room and I would hardly call it a clean environment

Two questions…

- What’s up with that?

- You got a side counter fitting business going on?

- I lied it’s 3 questions, what was your address again

(All in good fun)

Haha the tape dispenser was free from work. I am also a cheapskate.

Lol it’s ok. I have a tape dispenser my kids made for me. It’s a regular tape dispenser that they got ahold of the label maker and made comicsheatingup labels for. No confusing whose tape dispenser is whose.

I would definitely stay low temp if you are not using 65 lb stock between the cover and the book. Once you get to higher temps on moderns, if you do not do a full stack like the one I mention in my link, the pages can fuse together.

Nobody’s stealing my tape.

One time I found a beat to shit copy of goon 1 in a .50 bin. I pressed it but unbeknownst to me my wife had used the press to I guess iron. Something  the heat was on 300. Yeah that wasn’t pretty pretty much every page was stuck to the next. I still sold it for $20 after.

the heat was on 300. Yeah that wasn’t pretty pretty much every page was stuck to the next. I still sold it for $20 after.

I’ll definitely go get some and try it out. I tried using just plain ole printer paper but noticed a line pressing into the cover from the underlying piece. Do you have a secret way of making the piece under the cover sink in better?

It is possible that the line might be a sign of using too much pressure. How much force do you have to exert to lock the press? I use my non-dominant hand to close the press and make sure I can close it with a loose wrist (if that makes sense).

When I am applying the 65 lb cardstock, I basically just place the spine of the comic in one palm and open the cover (like you are going to read it) and slide the paper all the way to the back. then when I close the book, I use my thumb nail to apply some pressure to the paper to make sure its as far back as possible. I never get lines doing this.

Another benefit I find of the cardstock is that it supports the spine better helping get rid of tougher spine ticks.

It’s possible there’s too much pressure. I’ll go get the supplies and try it out on something some time this week. I’ll get back to you with my results.

omg I have so many crappy comic books that I dont care if they get ruined that I want to experiment on with my press when it gets here lol

I just dumped 3 short boxes of worthless books at half price yesterday… but all were in NM already… after they get put in the bins at half price, they’ll become VG to VF in no time…

I sometimes find gold at HPB for good prices. Love when they do a coupon for anywhere from 20% off to those rare 50% events.

Yup and while I was there this round, I noticed my Bendis signed slightly damaged (small spine ticks on lower corner) Civil War II that I couldn’t even sell for $5 on eBay at one time, they had in their special glass case and were trying to sell for $100… I had a good chuckle on that one… it’s gonna be there for quite sometime me thinks.

Hey @PCKComics , Great list and tips, also thanks for the parts blog!

Had a question about your comment on never putting moderns in a humidity chamber. Recently had a water leak that soaked some modern books to varying degrees (mainly 2019-2020 issues, and sadly some great books and hot indies like SiKTC  ).

).

Some seem completely trashed, some have bad cover wavering, and some just a few bubbling spots. They have been dried out for a few weeks now, and was thinking of trying out home pressing.

Given this scenario what are your thoughts on humidification on these moderns before a press?

Any one have other ideas or recommendations for a situation like this?

No problem, happy to help.

The tough thing about pressing is that different comics react differently to certain approaches. Reasons for this could be different paper types, degrees of damages, or even ink colors. If the books have already been wet, they probably would not be further damaged by humidity and may even be improved, but my advice is always to start with the path that has the least chance of damaging a comic before advancing.

If the damage is mainly cover warping, the first thing I would do is a quick press (165 degrees for 5 minutes using the layering listed at the bottom of the material list).

If further improvement is needed, I would use my hand steamer (with distilled water only) on one side of the cover at a time and press. For the hand steamer you just turn it on away from the comic and than bring the comic into the steam, about 6 inches away, after it has started (this is to avoid sputtering of water). Then, just as you would if you were steaming a garment sweep over the areas without stopping. You only want enough steam to give the cover a bit of a sheen, you don’t want it wet.

If none of that gives you the results you want and you are willing to take the risk, you can go to the humidity chamber. Again, starting off slow. Do you have a humidity chamber? If so, I would just put about 3 cups of distilled water in the bottom and leave it in for about 12 hours and try another quick press. If you dont have one and do not know how to make one, let me know and I can help you with that as well.

My guy not only dry cleans, but he cleans the staples too, if required (hopefully not, I’ve needed it done only once  ).

).

Having trouble sourcing the 9 x 12 x 1/8 steel plates that PCKComics recommends for the press machine. Anybody know where these can be purchased?