Do you think this will survive?

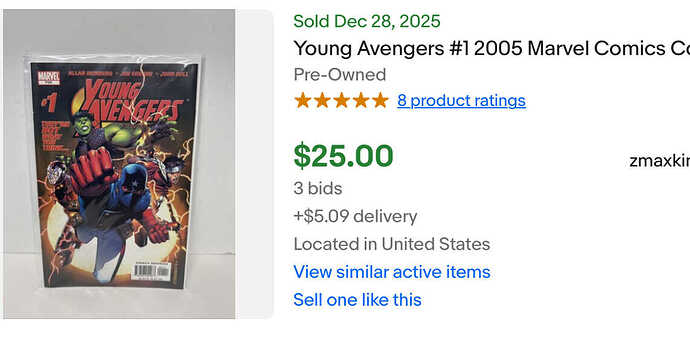

eBay is my price guide…

But at $2.99 I’ll pick up a copy. At least it’s starting with the right cover.

I wonder if borders, BAM and other non-comic ship places will carry it. If so, that’s a good thing. Especially for ABM…like it needs any more hype, but a mass marketing of this magazine cod introduce more people into (or back into) the hobby.

Unsure on the book stores. Yeah the price point is attractive for a magazine. If they could squeeze in some sneak peaks, or maybe a cameo, I could really see it taking off.

I picked up the free number zero issue not long ago. It’s not bad. I’ve been dying for a wizard style magazine. I really miss wizard.

I have no clue when it comes to figures. Will this affect values on playmate TMNT?

Looks like they are not going to make TMNT figures any longer.

Sold my last first print Absolute Batman #1 this past week (Lee) and most of my first print ALL in Special #1… Didn’t go huge on it but sold enough to pretty much pay for the gaming pc my kid wanted for Christmas. He is young so not an ultra set up, but a nice mid range, entry level rig. That and a monitor all for right around a seventy dollar initial investment with shipping (give or take). .

Saw people talking about taking the Lee cover off and turning them into A covers. Said cgc didn’t notice. I don’t agree with this by the way.

This book is falling on hard times. Lots of Marvel books can be gotten cheap now, assuming you think they will ever increase in value again.

Here’s one for any of you electrical nerds.

My treadmill bed suddenly stopped moving (motor

Would not turn). Sometimes if I force it to move, it will eventually “kick in”.

At first I thought it was a bad capacitor maybe not sending an initial charge…and forcing the motors to spin manually may be jump starting it…that was an issue with my pool pump motor…but I don’t think that’s it.

Watched a tutorial about how to check if your motor is bad…you can unplug the motor terminals from the board and connect them together via a paper clip…this will charge the magnet in the motor and it will be harder to turn because of increased resistance (vice when the magnet is off). If it still spins freely (magnets not charged) then the motor is bad. Well, mine has resistance when the terminals are connected or not…as if the magnets are continually charged.

So I was trying to see if there was any voltage going to the motor using the paper clips and accidentally one of the paper clips while connected to the negative terminal touched the side of the motor and there was a HUGE spark…and the motor started right up (throwing everything I had sat in it across the room). Welded the paper clip instantly to the side of the motor too. Must’ve been really hot!

Anyway…did a little research about sparking motors and learned about these things called “commutators” and “brushes” which have to do with creating north/south polar charges which cause the motor to move…and the commutators can get dirty from the brushes (which are carbon blocks basically) which messes with the charge creating magnetism…

Looking at the commutator it does seems to need to be cleaned…can use a pumice stone or 1000 grit sand paper to get them l down to shiny copper again.

Since being shocked into coherence, it does seem to “stutter” a bit when trying to start. So maybe it is a simple fix.

So if you’re still with me…wondering if anyone who knows anything about motors thinks this makes sense…that a dirty commutator could cause a motors not to start…but after rotating the motor it might start up.

Clearly the motor is able to run/not burnt out …and the control board is sending a signal. Not sure what else it could be.

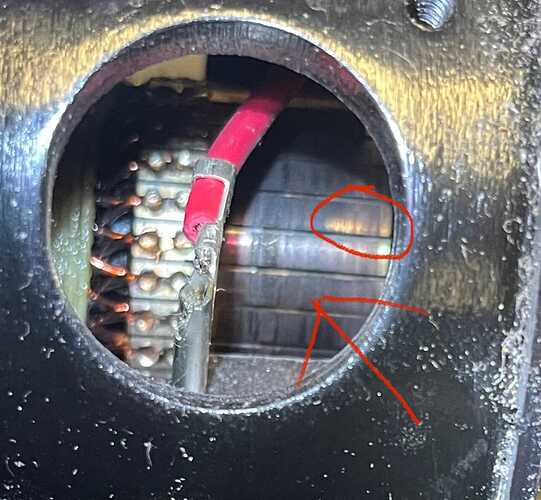

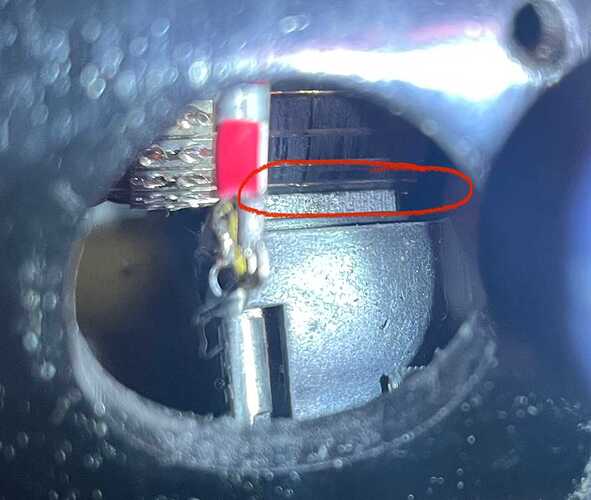

Here are some pics.

Motor and access port.

Copper commutator…circled an area that is the color it’s supposed to be (clean copper).

Angle looking at where the “brush” (carbon block) contacts it (circled).

I am not mechanical and will have to pass to someone with an engineering degree.

Mechanics tend to curse engineers… engineers should spend time working on the things they design, in the auto field there have been some doozies. Lifting an engine to change spark plugs is one that comes to mind.

I’ve worked on cars for a long time and I hate messing around with electricity. More because I have gotten shocked waaaaay to many times.

Needless to say, the copper inside the motors need to be cleaned. Dirty copper does not conduct electricity. This I know becuase I have rebuilt an alternator and had to put new coper wire on it in order for it to hold charge.

Maybe a nice clean will help with the charge?

I can share my latest tinkering with this. When I hit start the motor/pulley didn’t do anything…which has been typical. The past week I’ve had to force the tread to move and on occasion it would pick up. If the pulley doesn’t move within a few seconds the E-1 error code shows up and I have to turn the power off to reset.

So with the motor/pulley exposed this time, rather than walking on the tread, I tried rocking the pulley wheel back and forth lightly (and prevents the E-1 error) and the motor struggled/stuttered a bit, but the magnets eventually took over and it started to spin.

I rocked it because I felt it needed help finding the “sweet spot” for the polar opposite magnets to do their thing…so this leads me to believe even more it’s the thing I mentioned above which I now forget what it’s called…

My background is Civil engineering…but I’ve tinkered enough with electricity and moving parts to at least understand things if someone explains them to me (like on you tube). Seems like I’m on the right track…

The staples would be a bit loose I would think. I guess they could be flattened/tightened a bit and with CGC being so careless these days it might go unnoticed.

Yeah, I loved Wizard back in the day but honestly, if we got rid of the internet maybe a magazine like it would survive again. The problem with monthly magazines nowadays is, the time it’s printed and before it’s even packed on the trucks to ship out to retailers for consumers to buy, most of the information is already outdated… ![]()

If you can source the correct brush, are able to access the panel on the bottom to remove the old brush, install a new brush, clean the commutator (also between the bars), and remove all of the carbon dust after cleaning, then give it a go. Most repair people will say to replace the motor, because it’s not easy to source the brushes on top of all the other stuff. You can’t use generic brushes with generic springs. You could try cleaning/smoothing the surface of the brush, but it might be too worn down. I would get a new motor if I couldn’t get the correct brush. I can’t find your brush based on your motor, but you may be able to find it based on your Treadmill Model. The whole process may not be worth it.

Same here but I’m not afraid of electricity. Girlfriend loses her mind when I’m doing replacements around house and I’m like… just turn the switch off, and she insists I turn the breaker off and I’m like… that’s just more work!!!

I’ve had a few scares too but I keep coming back… either that or I’m dead and none of this is real and I’m in the afterlife still getting older and feeling older every damn day I wake up… ![]()

I’m afraid of shutoff valves. I swear, every one I touch breaks. Now I just go out to the main one piss off the whole house, but too bad.

The exact same treadmill is about $100 more (new) than the motor.

I’ve gotten treadmills for free. If I can’t fix it myself I’ll wait for another one to show up on buy-nothing. When people are done with them they just want someone to take them away…

My last one made it 5 years and the only reason we gave it away was because we got this newer model. Which didn’t last more than a year…my wife liked this one better (I was skeptical) but I’m the only one who uses it. (Sigh…)

I have a current detector i use, because how do you even know you threw the right breaker? I have a wand and one that plugs into an outlet which checks the ground as well.

I make sure they work by testing it on live wires/outlets before relying on it. But yes, I don’t turn off breakers unless something is hard wired…I rely on properly functioning tools to tell me if something is safe.